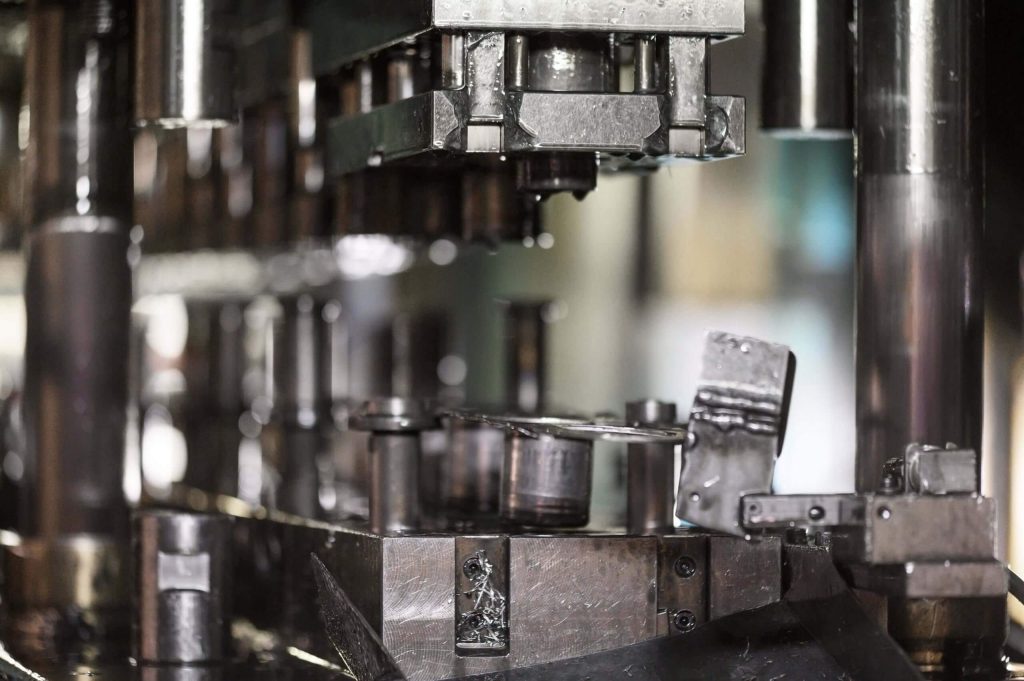

Precision stamping requires high precision and durability from every component involved in the process. Coatings help maintain consistent product quality. By minimising seizure, sticking, and wear, coatings help maintain the integrity of the stamping die. This reduces downtime, changeovers, and maintenance costs.

Types of Coatings Used in Stamping Dies

Several types of coatings are commonly used in Precision Stamping tools. Among the most popular are Titanium Nitride (TiN), Titanium Carbonitride (TiCN), and Diamond-Like Carbon (DLC). Each coating offers unique properties that cater to specific production needs. For instance, TiN offers excellent hardness and wear resistance, while TiCN enhances lubricity and is particularly suitable for abrasive materials.

On the other hand, DLC coatings offer superior performance in dry and high-speed stamping applications. They reduce friction and increase surface hardness, significantly extending tool life. Choosing the right coating requires a thorough understanding of the stamping environment, including material type, stroke speed, and part geometry. In many cases, collaboration with coating specialists ensures the optimal match for your Precision Stamping operation.

Impact on Wear Resistance and Friction Reduction

Wear resistance is a significant concern in high-volume stamping operations. Every punch, draw, or form subjects the tooling to tremendous mechanical stress. Coatings like TiN and TiCN form a hard surface layer that withstands this stress and reduces surface deterioration. This results in better dimension control and prolonged die life.

Friction reduction is another critical benefit. Lower friction means less heat, resulting in decreased thermal expansion and distortion. In turn, this helps maintain tighter tolerances and improves part consistency. Especially in Stamping dies, where repetitive motion is continuous, reduced friction drastically enhances tool longevity and production uptime.

Influence on Surface Finish and Part Quality

The quality of the final stamped part is often a reflection of the condition of the Stamping dies. Coatings play a pivotal role in preserving surface smoothness and finish. Smooth, coated surfaces prevent material from sticking, thereby reducing the likelihood of surface defects such as scratches or pits.

Consistent part quality is crucial in industries like automotive and aerospace. Minor imperfections can lead to significant failures in critical applications. Therefore, using the right coating not only preserves the die but also ensures each part meets stringent specifications. This dual benefit of quality and durability is vital for maintaining production standards in Precision Stamping.

Extended Tool Life and Cost Efficiency

Extending tool life directly translates to cost savings. Coated tools last longer, meaning fewer replacements and lower tool inventory costs. This is particularly important in Precision Stamping, where the cost of tooling can be a significant portion of the total manufacturing expense.

Moreover, longer tool life reduces downtime for maintenance and die changes. This leads to increased machine availability and higher overall throughput. Over time, the investment in coatings pays for itself through reduced operational interruptions and enhanced productivity.

Enhanced Performance in High-Temperature Conditions

Stamping operations generate considerable heat, especially during high-speed or deep-draw processes. Coatings enable tools to withstand elevated temperatures without compromising their hardness or shape. For instance, ceramic-based coatings can maintain integrity even at extreme temperatures.

Maintaining tool geometry at high temperatures is crucial for Precision Stamping. Any thermal distortion can compromise die alignment and part accuracy. With the right coatings, tools maintain their form and performance under stress, ensuring reliable output even in the most demanding production environments.

Coating Selection Based on Material and Application

Not all coatings are suitable for every material or application. For example, softer metals like aluminium may benefit more from DLC coatings, while harder steels might require TiCN or even chromium-based solutions. Understanding the interaction between the coating and workpiece material is essential.

Additionally, the complexity of the part and the nature of the stamping process influence the choice of coating. Progressive dies, for instance, may need different coatings for various stages of the process. Customising the coating strategy enhances both performance and tool longevity, ultimately making your Precision Stamping operation more resilient and efficient.

Coatings as a Strategic Investment in Precision Stamping

In the competitive manufacturing landscape, maximising the efficiency of your Precision Stamping process is non-negotiable. Coatings offer a strategic advantage by significantly extending tool life and ensuring consistent part quality. From wear resistance to thermal stability, their benefits are multifaceted and measurable.