One-Stop Service Guide for Non-Standard Mold Base Solutions

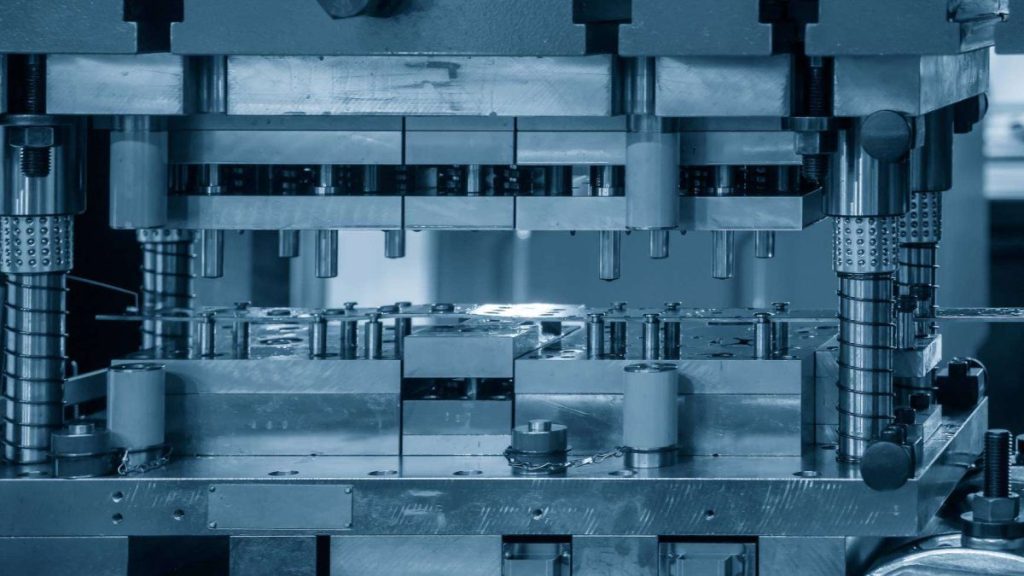

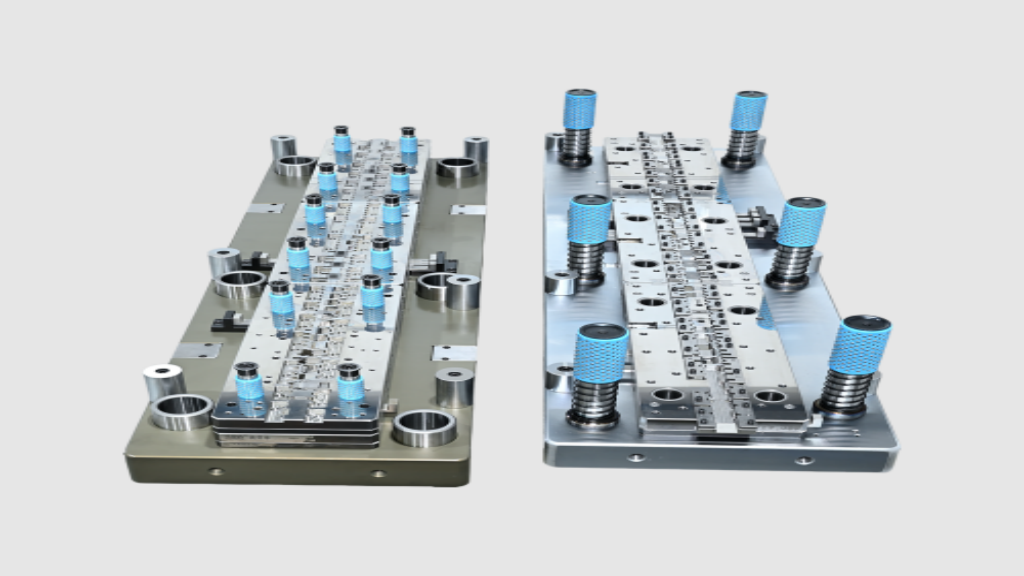

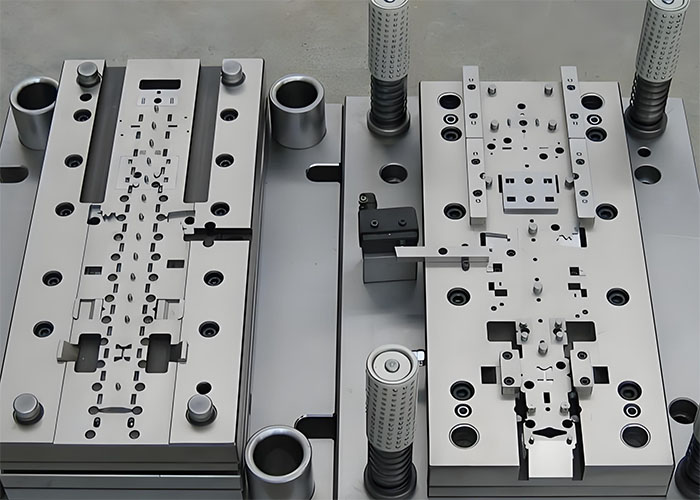

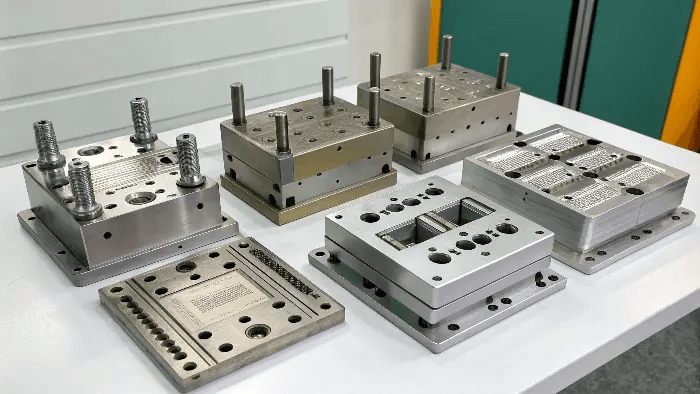

When standard mold bases fail to meet your needs, your project requires a collaborative mold fabrication service manufacturer that can provide end-to-end customized solutions encompassing design, fabrication, assembly, and support. Chaoyang offers a one-stop service for non-standard mold bases, integrating engineering design, materials science, precision machining, surface treatment, and full lifecycle support into a traceable workflow. The result includes faster turnaround times, fewer handover steps, predictable tolerances, and mold bases that can be seamlessly integrated into your stamping unit. What does a one-stop non-standard mold base service include? Non-standard mold bases become crucial when standard mold frames cannot meet functional or dimensional requirements. Chaoyang provides a one-stop service, integrating engineering design, material selection, precision machining, assembly, and full lifecycle support into a unified workflow. Clients no longer need to coordinate multiple suppliers; they only need to work with one partner responsible for the entire non-standard mold base fabrication process. Our services encompass requirements analysis, 3D design, finite element analysis and simulation, raw material procurement, CNC machining, EDM, precision grinding, heat treatment, surface treatment, assembly, inspection, and after-sales support. By internally integrating these steps, we reduce dimensional deviation risks, shorten production cycles, and ensure consistent quality control. This integrated approach improves efficiency while reducing the total cost of ownership. More importantly, it ensures that each non-standard mold base is meticulously designed for durability, alignment accuracy, and long-term production reliability. Non-standard Mold Base Precision Design and Simulation The success of non-standard mold base machining begins with rigorous engineering verification. Our design team develops 3D CAD models based on customer drawings and functional requirements. Before manufacturing begins, we utilize advanced simulation tools to analyze structural strength, stress distribution, thermal effects, and forming properties. Finite element analysis (FEA) enables us to predict deformation risks and optimize load-bearing structures. Design Failure Mode and Effects Analysis (DFMEA) further ensures early identification of potential weaknesses. This proactive engineering process minimizes redesigns and accelerates project progress. Furthermore, our engineers optimized tolerance allocation, benchmark strategies, and modular structural design. Replaceable inserts and wear parts were used whenever possible to simplify maintenance. Therefore, each non-standard mold set is not only customized but also meticulously designed to ensure operational stability and long-term maintainability. Material, Heat Treatment, and Durability Optimization Material properties directly affect the service life of non-standard mold sets. Chaoyang selects tool steels such as D2, A2, and H13 based on wear resistance, impact load, and heat exposure requirements. For high-wear areas, we integrate carbide inserts or hardened wear-resistant plates to extend service life. The heat treatment process is strictly controlled to balance hardness and toughness. We employ vacuum quenching, tempering, and stress-relief cycling processes to compensate for thermal deformation generated during subsequent grinding. Hardness verification and microstructure inspection ensure the integrity of the metallurgical structure. Surface enhancement treatments such as nitriding, PVD coating, and chrome plating further improve wear resistance and corrosion resistance. Through these controllable processes, we employ non-standard mold base machining technology to achieve high structural stability, dimensional retention, and predictable performance under stringent production conditions. Non-standard Mold Base Machining Equipment and Process Control Precision machining is the cornerstone of all non-standard mold bases. Chaoyang Company possesses advanced multi-axis CNC machining centers, wire EDM machines, EDM machines, high-precision grinding machines, and coordinate measuring machines (CMMs). These devices enable strict tolerance control for complex geometries. Our machining process typically includes rough milling, EDM, heat treatment, fine grinding, lapping, and final assembly preparation. Temperature-controlled workshops and online distance measurement systems ensure consistent dimensional accuracy. Because we complete all major processes in-house, we maintain full traceability and minimize the cumulative errors that outsourced processes may cause. This closed-loop manufacturing system ensures that each non-standard mold base meets stringent geometric tolerance, parallelism, and alignment accuracy standards. Quality Assurance and Assembly of Non-standard Mold Base Solutions After machining, precision assembly ensures functional reliability. We follow standardized alignment procedures, employing controlled torque values and calibrated assembly tools to prevent deformation. Guide pillars, bushings, and sliding components are installed with precise fit tolerances to maintain long-term stability. Dimensional inspection includes coordinate measuring machine verification, flatness testing, perpendicularity checks, and surface roughness measurements. For progressive dies, we conduct trial punches to verify strip flow, punch clearance, and indexing stability. Each non-standard die set provided by Chaoyang comes with a complete documentation package, including inspection reports, material certificates, and heat treatment records. These documents ensure transparency and simplify the customer’s qualification process. Surface Treatment, Coating, and Wear Management Surface treatment is crucial to product performance. Chaoyang offers processes such as nitriding, PVD coating, hard chrome plating, and anti-corrosion treatments, depending on application conditions. These processes reduce friction, decrease wear, and improve durability. Wear parts feature a replaceable modular design. Customers can quickly replace punches, inserts, or wear plates without disassembling the entire non-standard die set. This modular design reduces downtime and simplifies maintenance planning. We also provide recommended spare parts packages based on projected production cycles. By aligning consumables planning with production schedules, customers can maintain operational continuity while controlling maintenance costs. Get Reliable Customized Non-Standard Solutions From engineering validation and material optimization to precision non-standard mold base machining, controlled assembly, and full lifecycle support, Chaoyang offers a one-stop integrated solution for non-standard mold bases, designed to eliminate uncertainty at every stage. Our unified and coordinated system manages design, machining, heat treatment, inspection, and after-sales service, allowing customers to enjoy shorter lead times, tighter dimensional control, and lower total cost of ownership. More importantly, each non-standard mold base is designed not only to comply with current specifications but also to support high-volume production with predictable performance and simplified maintenance.