Understanding Tolerances and Surface Finishes for Precision Machined Parts?

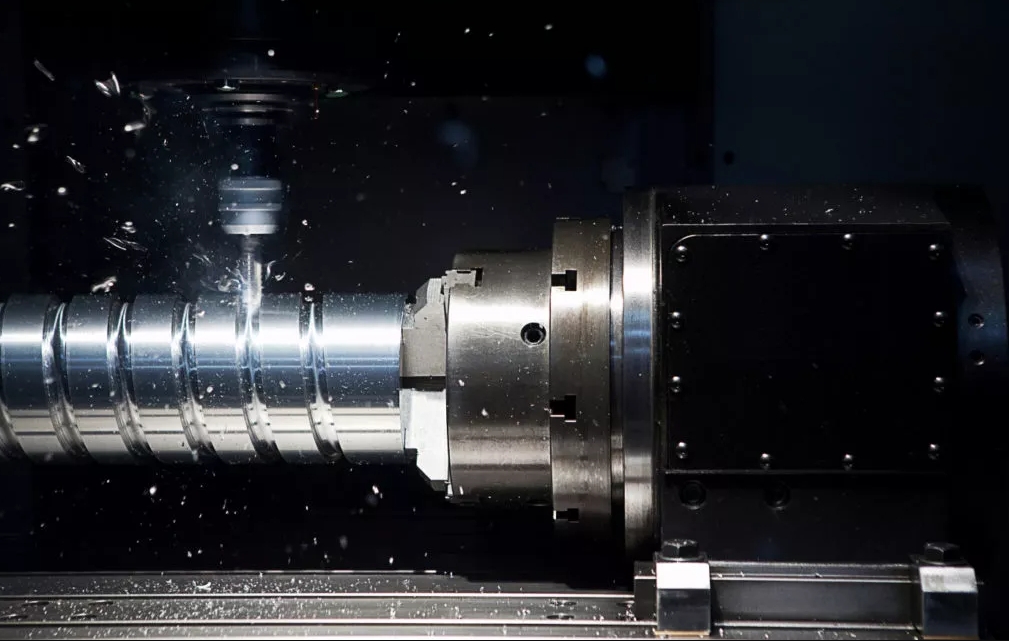

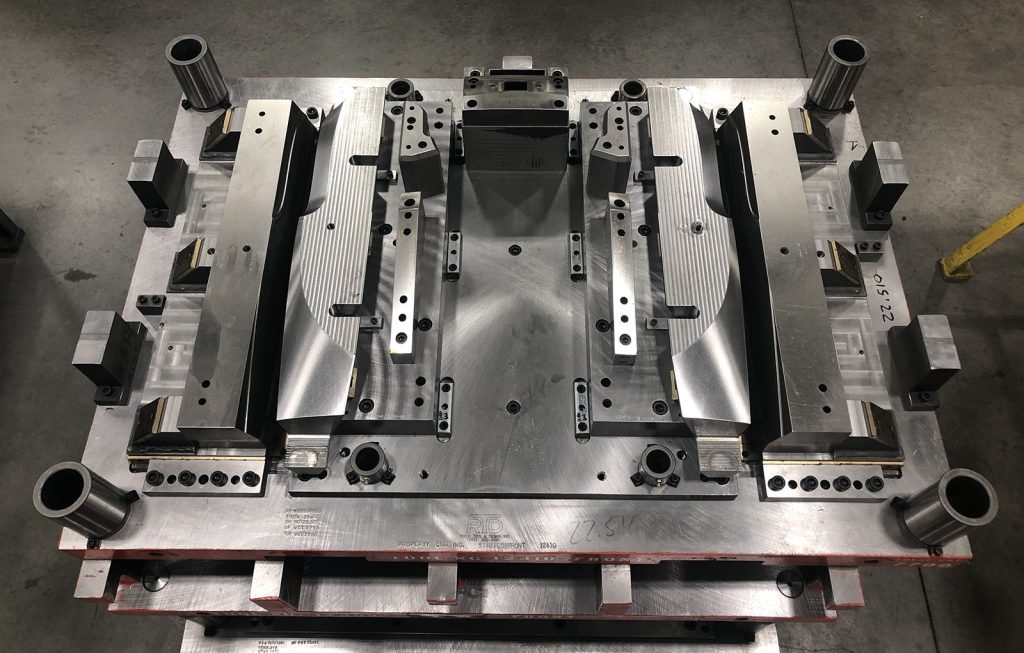

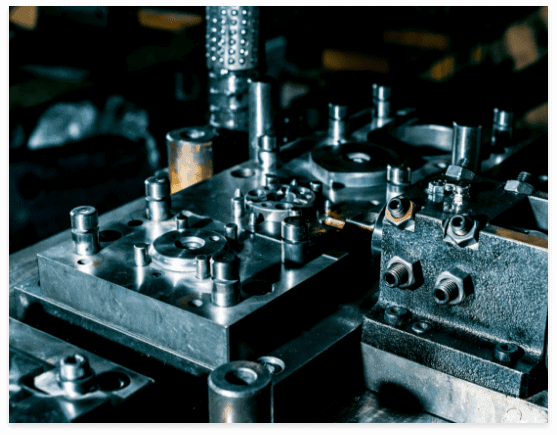

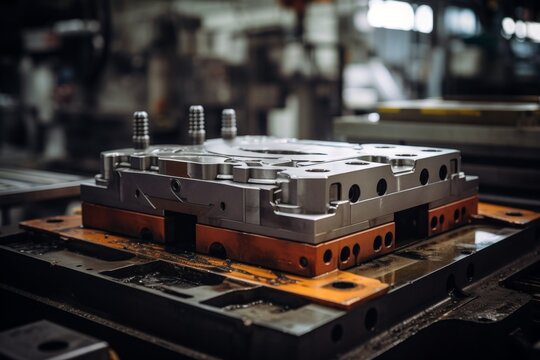

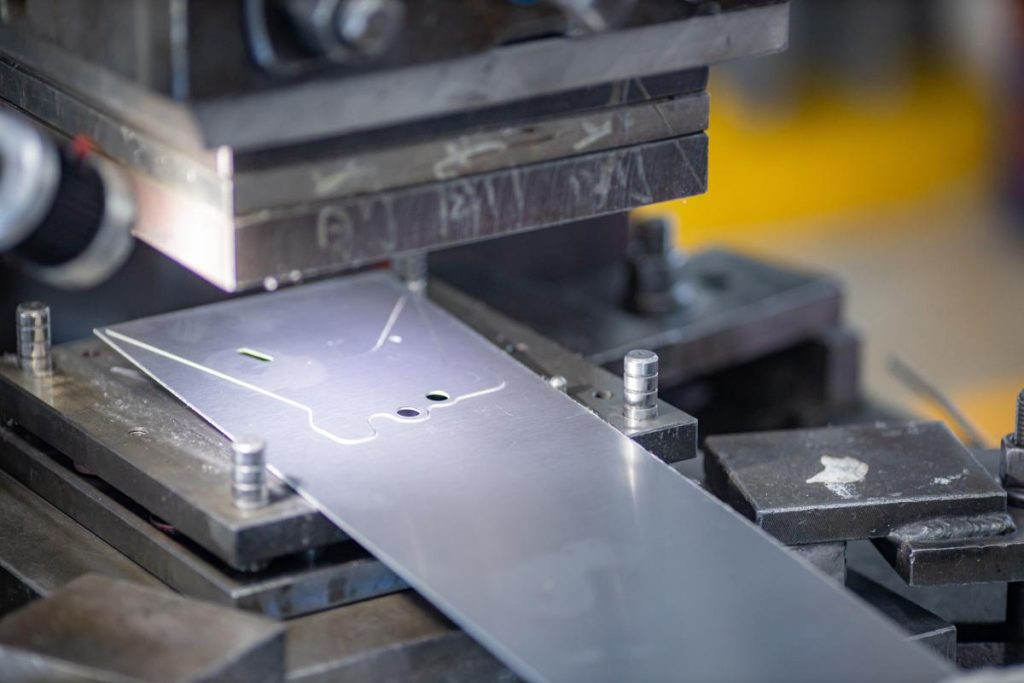

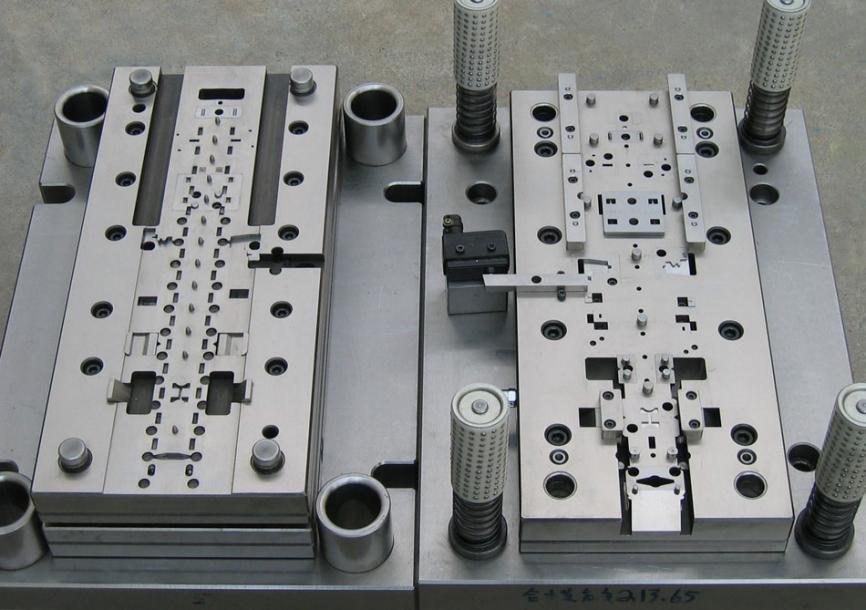

Precision-machined parts are needed in a wide range of fields, from aerospace to medical devices. These parts require precise specifications to ensure optimal functionality. Manufacturers rely on precise tolerances and surface finishes to meet stringent performance requirements. Without proper attention to these factors, parts may not fit, work properly, or last as long as expected. By understanding tolerances and surface finishes, companies can improve product reliability, reduce costs, and increase efficiency. Defining Tolerances and Why They Matter Tolerances define the allowable variation in a part’s dimensions. They ensure that even with slight deviations, components still fit and function correctly. Specifying tolerances too tightly can unnecessarily drive up manufacturing costs. Conversely, loose tolerances may compromise product performance. To select the correct tolerances, engineers evaluate factors such as function, material, and assembly method. Standardized systems, such as ISO and ASME, provide widely accepted tolerance classifications. Understanding these guidelines enables businesses to specify precise yet cost-effective tolerances for their precision-machined parts, ensuring consistency across production batches and among suppliers. Exploring Surface Finishes and Their Functional Impact Surface finish refers to the texture and smoothness of a part’s surface. It affects more than just appearance. Surface finish influences friction, wear resistance, and sealing capability. In some industries, such as aerospace, it also affects fatigue strength. Various measurement methods, such as Ra (average roughness) and Rz (maximum roughness depth), quantify surface finish. Engineers select the ideal finish based on the part’s intended function. By optimizing surface finish, manufacturers improve component performance while controlling machining time and costs. Choosing the right finish is crucial for producing high-quality, precision-machined parts. Balancing Tolerances and Surface Finishes for Cost Efficiency A common challenge in machining is balancing tight tolerances and achieving smooth surface finishes. High-precision machining can become costly if specifications are stricter than necessary. Therefore, businesses should prioritize critical areas while easing requirements in other areas. Collaborating with experienced machinists early in the design phase helps optimize both factors. Advanced tools, such as CAD simulation and tolerance analysis software, enable teams to predict how different tolerances and finishes will interact with each other. This proactive approach prevents over-engineering and ensures cost-effective manufacturing of precision-machined parts without sacrificing functionality or durability. The Role of Material Selection in Achieving Desired Specifications Material properties directly influence achievable tolerances and surface finishes. Metals like aluminium, steel, and titanium each respond differently to machining processes. Softer metals may be easier to machine, but they are prone to scratches. More complex alloys offer better durability but require specialized tooling. When selecting materials, engineers must weigh cost, machinability, and performance. Often, a compromise is necessary to strike the best balance between ease of machining and the final part’s performance. Understanding material behaviour under machining conditions is critical for producing reliable precision-machined parts that meet both design and budget goals. Advanced Machining Technologies for Tight Tolerances and Fine Finishes Technological advancements have revolutionized machining capabilities. High-speed CNC machines and multi-axis systems allow for unparalleled precision and consistency. These machines can maintain extremely tight tolerances and deliver fine surface finishes in a single setup. Additionally, emerging technologies such as electrical discharge machining (EDM) and laser machining expand the possibilities for producing intricate designs. By leveraging these technologies, manufacturers can create complex, precision-machined parts with minimal post-processing requirements. Investing in advanced machinery also reduces waste, shortens lead times, and enhances overall product quality. Quality Control and Inspection for Consistent Performance Quality control plays a pivotal role in ensuring that machined parts meet their specified tolerances and surface finishes. Coordinate measuring machines (CMMs) and optical scanners provide accurate dimensional verification. Regular inspections during production help catch deviations early and prevent costly rework. Moreover, surface finish testers offer quantitative assessments of surface roughness. Businesses that implement rigorous inspection protocols reduce defects, improve process repeatability, and boost customer satisfaction. Effective quality control is not just about compliance. It’s a proactive strategy to maintain high standards for every batch of precision-machined parts produced. Optimising Tolerances and Surface Finishes for Precision Machined Parts Success In the world of precision-machined parts, tolerances and surface finishes are more than just technical details; they are essential to the overall quality and performance of the part. They determine the function, fit, and long-term durability of the parts. Through the selection of reasonable materials, advanced processing technology, and strict quality control, companies can enhance product performance, reduce costs, and improve reliability.