How Coining Techniques Add Fine Detail to Precision Metal Stamping Parts?

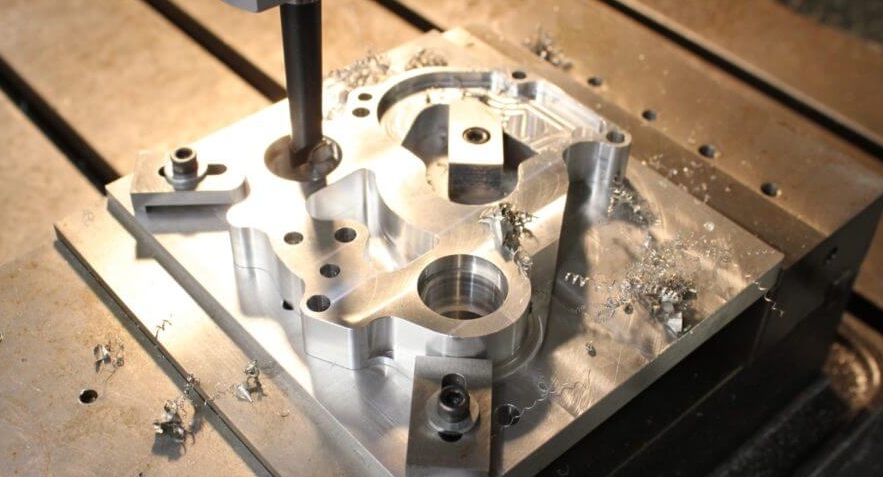

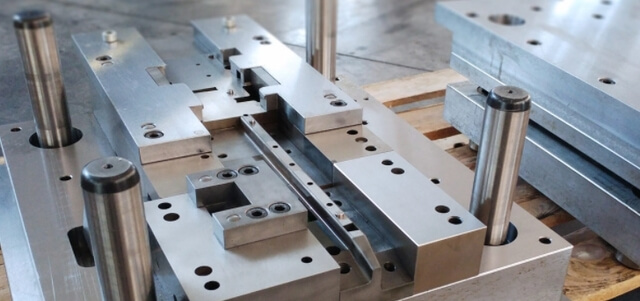

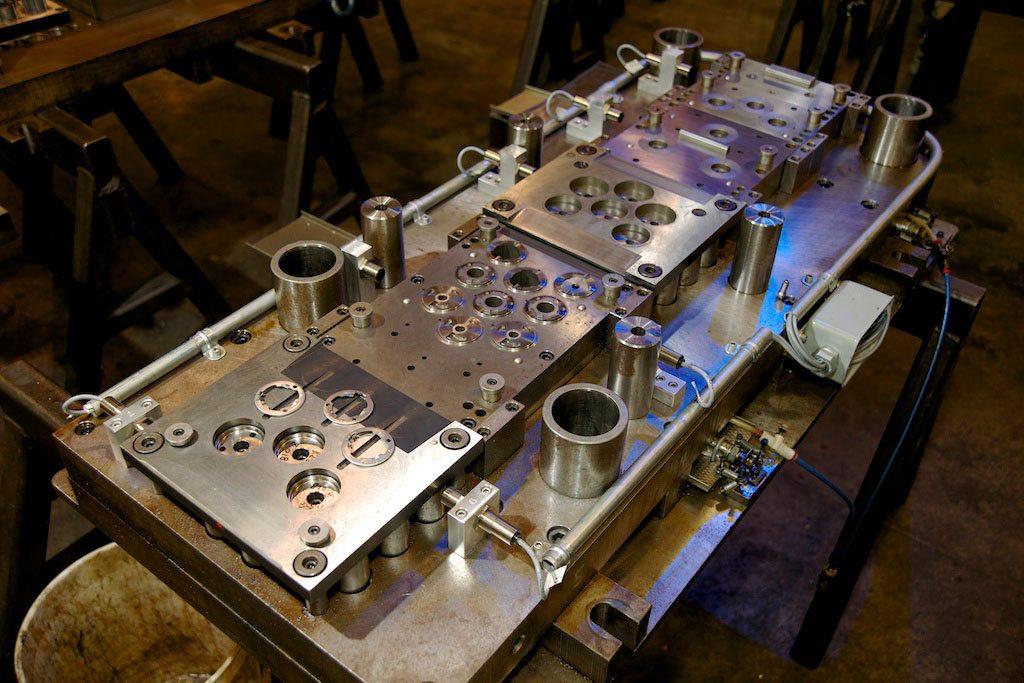

Coining refines stamped metal with high precision. It compresses metal into die cavities. As a result, minute features appear sharp and repeatable. In practice, coining follows primary forming steps. Therefore, you achieve both gross geometry and fine detail on Precision Metal Stamping Parts. This piece explains how coining works, why it matters, and how manufacturers control it. Read on for practical, no-fluff guidance. Engineers maintain tight tolerances and consistently achieve desired outcomes in daily production. What Coining Actually Does Coining forces a punch into metal at high tonnage. The metal flows into the die under compression. Consequently, tiny features fill. Additionally, edges are sharpened and profiles are crisp. For instance, embossed logos, fine text, and contact pads gain clarity. In addition, coining compresses the surface layer. Thus, local hardness and wear resistance improve. As a result, parts retain their details throughout the assembly and service process. Technicians confirm embossed logos and contact pads meet spec consistently. Why Tooling Precision Matters Tool design sets the limit for achievable detail. Designers must machine cavities to exact tolerances. They must also control surface finish and radii. Otherwise, flaws transfer to thousands of parts. Moreover, the alignment is critical. If the punch misaligns, the features blur. Therefore, robust guiding and regular maintenance pay off. In short, tooling quality equals part quality. Regular inspections prevent wear-related defects and save costly production downtime. Process Parameters That Drive Outcomes Press force, stroke speed, and dwell time alter the behavior of metal. Increase the force to push metal into deep cavities. Yet, excessive force raises wear and scrap. Conversely, slower strokes often aid full fill. Thus, engineers conduct trials to find the optimal setting. Additionally, monitor temperature and lubrication levels. For some alloys, heat helps flow. Meanwhile, proper lubricant reduces galling and scoring. Operators adjust settings and log results to facilitate continuous improvement daily. Material Selection and Metallurgy Different metals respond differently to coining. Copper and its alloys fill fine features well. Stainless steels demand a higher force but retain detail once formed. Additionally, grain size affects flow and finish. Therefore, pre-treatment, such as annealing, may improve results. Also, consider plating or coatings. They change friction and can affect fill quality. Match alloy choice to the required feature size and production volume. Select alloys and treatments to match geometry and lifecycle demands. Inspection, Measurement, and Quality Control You must verify that the coin hit its mark. Use optical metrology to check micro-features. Also, apply tactile gauges for contact faces. Furthermore, functional testing in assemblies confirms fit. Track statistical metrics like Cp and Cpk. If capability drops, adjust tooling or process parameters. In addition, maintain traceability records. That makes root-cause analysis faster when issues arise. Traceability data helps engineers isolate problems and implement corrective actions. Production Benefits and Cost Impacts Coining often reduces secondary finishing. It removes burrs and improves surface finish at the source. Therefore, downstream grinding or manual deburring falls. As a result, the total cost of ownership can drop. Moreover, coined surfaces improve electrical contacts and sealing faces. For high-volume runs, coin tooling pays back quickly. In short, coining raises consistency and lowers unit cost over time. Investing in coining reduces rework and significantly improves long-term profitability. Applications Where Coining Shines Coining finds use in electronics, automotive, and aerospace. In electronics, it defines pads and embossed traces. In the automotive industry, it clarifies wear faces and fine locking features. In aerospace, it ensures fatigue-resistant detail. Consequently, coined parts perform better in tight assemblies. Also, coined markings resist wear, helping traceability. Thus, designers rely on coining when functional micro-features are crucial. Coining improves fit, function, and traceability across many demanding applications. Final Recommendations for Precision Metal Stamping Parts When you need fine detail, plan coining early. Specify feature tolerances and surface finish at the design stage. Then, select tooling materials and dies that match the expected tonnage. Additionally, run setup trials to fine-tune the force and speed. Use robust inspection and track process capability. Finally, consider the total cost, not just the cost. Properly applied, coining delivers sharper features, higher durability, and fewer secondary operations. For buyers and suppliers, insist on precise specifications and documented trials when ordering Precision Metal Stamping Parts. Document trials thoroughly to prove capability and support supplier selection.