How CAD/CAM Optimization Enhances Stamping Dies Fabrication Accuracy?

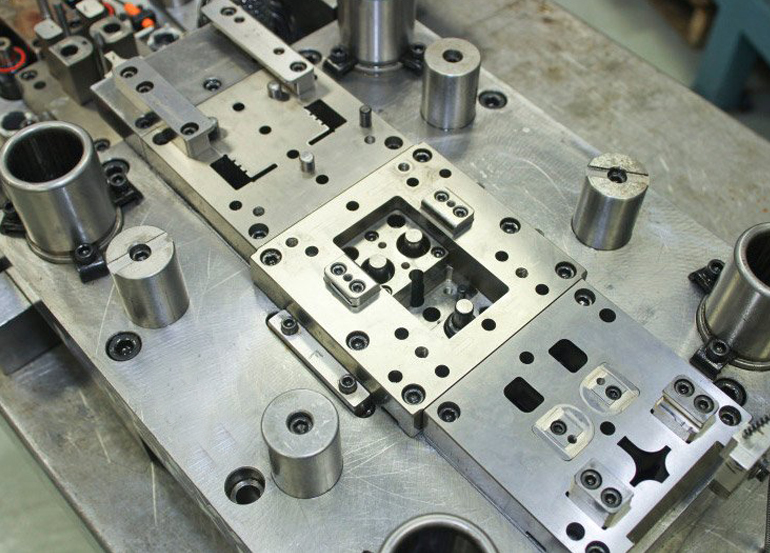

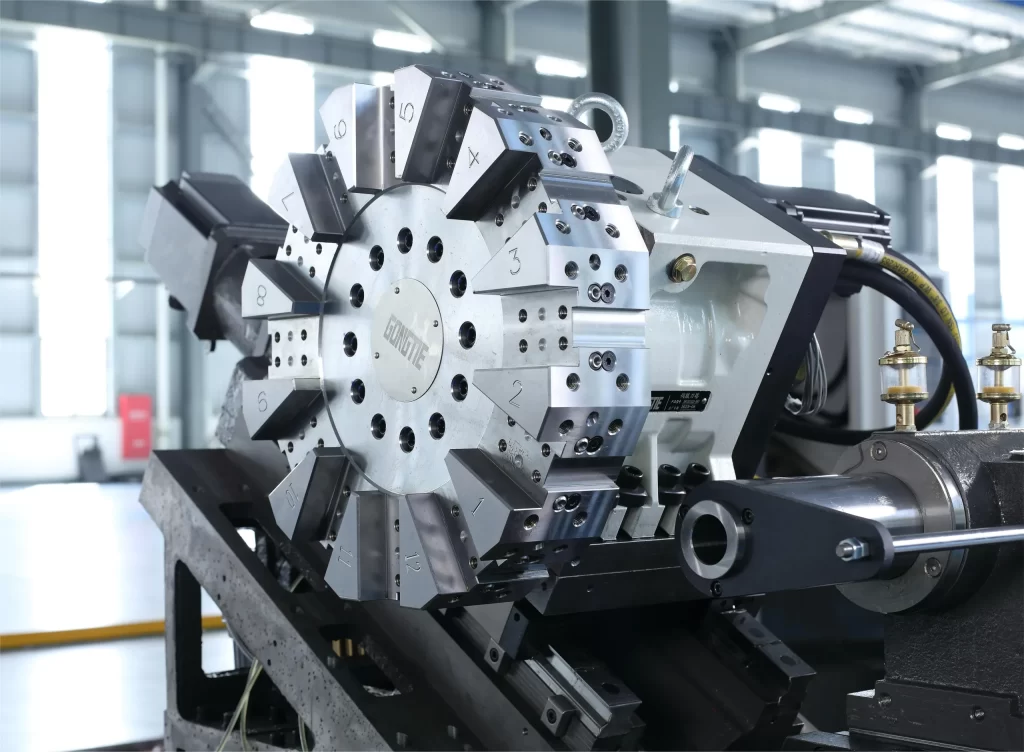

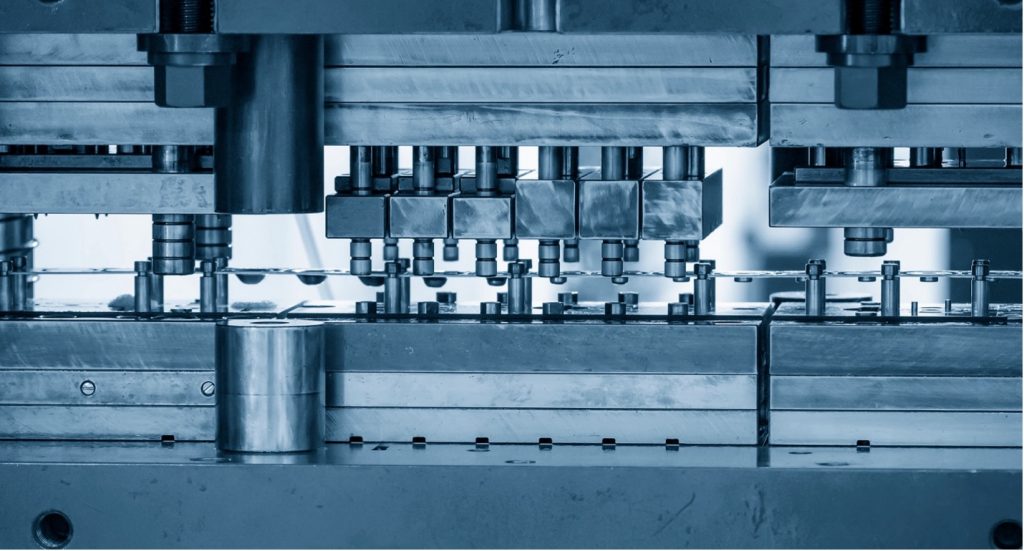

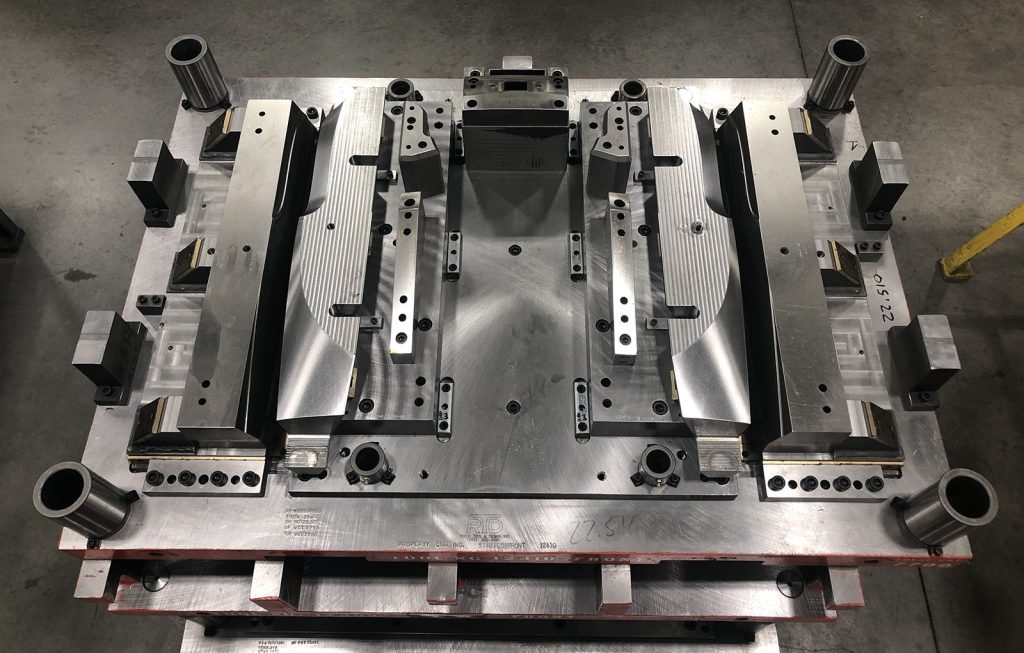

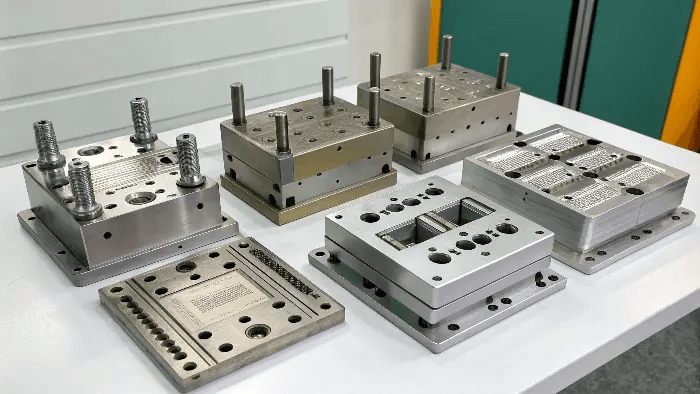

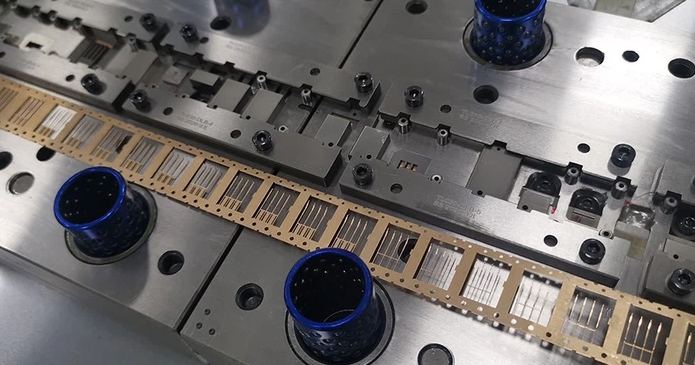

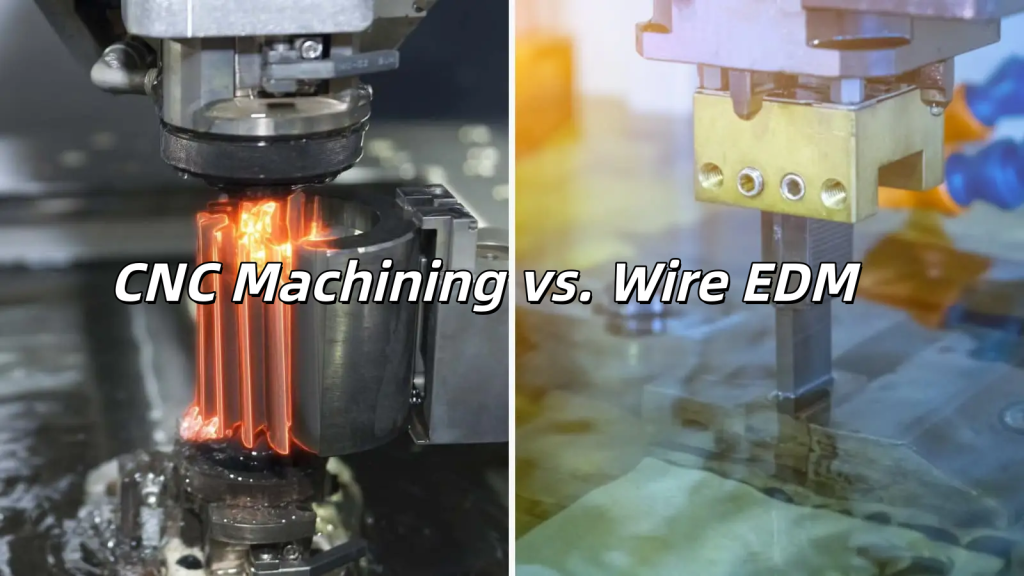

Manufacturers expect stamping tools to deliver stable accuracy across millions of cycles. However, traditional manual processes often introduce inconsistencies. CAD/CAM optimization changes this reality. It offers predictable modeling, faster design cycles, and tighter tolerances. Today, most high-performance Stamping Dies Fabrication workflows rely on advanced digital integration to reduce design errors and improve tool performance. Companies in automotive, consumer electronics, and connector manufacturing report that optimized CAD/CAM systems cut development time by up to 30% and reduce revision loops. These benefits make digital optimization a core requirement for modern tooling teams. Enhanced Design Precision Through Advanced CAD Modeling CAD modeling sets the foundation for die accuracy. High-resolution 3D models make it easy to verify each surface, corner radius, and relief area. Engineers use parametric features to control geometry and quickly adjust dimensions. This reduces mistakes and allows faster design iterations. CAD systems also support interference checks to detect fit issues between punches, dies, plates, and guide components. Many shops combine CAD with simulation tools to verify deformation patterns before machining. This step eliminates trial-and-error adjustments and protects the final Stamping die from misalignment problems. When CAD design is clean and consistent, downstream machining becomes far more accurate. Improved Toolpath Efficiency with CAM Optimization CAM optimization transforms a static CAD model into an efficient machining strategy. Modern CAM systems generate toolpaths that maintain consistent cutter engagement. This improves surface finish and dimensional stability. Advanced functions such as high-speed machining, trochoidal milling, and adaptive clearing reduce cutter load. These strategies also extend tool life, which helps maintain consistent accuracy throughout long machining cycles. When machining die components like punches, inserts, and form blocks, CAM optimization directly affects the performance of the finished tools. It ensures the geometry matches the CAD model with minimal deviation. Reducing Human Error with Automated Simulation and Verification Simulation helps teams validate toolpaths before cutting steel. CAM systems simulate cutter motion, spindle load, and collision risks. This process reduces human error and prevents costly crashes. Simulation also predicts tool deflection and machining heat buildup—two familiar sources of dimensional drift. When engineers review these simulated data points, they can adjust feed rates, cutter types, and workholding strategies before actual machining. Many companies report that digital simulation reduces machining problems by more than 40%. This dramatically improves the accuracy of final Stamping Dies Fabrication and lowers rework costs. Better Material Utilization and Tolerance Control CAD/CAM optimization ensures that material allowance, stock thickness, relief dimensions, and tolerance zones stay consistent throughout the design and machining workflow. Engineers specify detailed tolerance limits in the CAD stage, and CAM systems apply them to machining operations. This ensures consistency from roughing to finishing. It also maintains tight tolerances on cutting edges, form radii, and clearance areas. These areas directly affect stamping quality. When dies maintain precise geometry, stamped parts show fewer burrs, more consistent springback, and improved fit with downstream assembly. Accelerating Workflow Through Digital Integration Digital integration connects CAD, CAM, CMM measurement, and ERP/MES systems. This creates a closed-loop workflow. Engineers compare machined components with CAD data using coordinate measuring machines. When deviations appear, they update CAD/CAM models and apply corrections immediately. This reduces lead time and maintains accuracy during complex multi-stage Fabrication. Digital integration also simplifies version control. It ensures that all engineers, machinists, and quality teams use the same dataset, minimizing communication errors. Real-World Applications Across High-Precision Industries Industries such as automotive connectors, EV battery components, and consumer electronics benefit from CAD/CAM-optimized tooling. For example, connector manufacturers require ultra-tight tolerances on punch profiles, often within ±0.002 mm. CAD/CAM optimization enables consistent machining of these micro-features. Smartphone metal-frame suppliers use digital simulation to control springback during forming. Meanwhile, EV battery stamping lines rely on optimized die geometry to avoid burrs that could damage batteries. These real-world applications show that CAD/CAM is not simply an upgrade—it is essential for competitive Stamping Dies Fabrication. CAD/CAM Optimization Drives High-Accuracy Stamping Dies Fabrication CAD/CAM optimization provides measurable improvements for modern tooling teams. It reduces errors, improves machining efficiency, and strengthens accuracy across all die components. Manufacturers benefit from lower rework rates, faster development cycles, and more stable tool performance over millions of strokes. As demand for thin-metal components and complex geometries continues to rise, optimized CAD/CAM workflows will remain essential for high-quality Stamping Dies Fabrication.